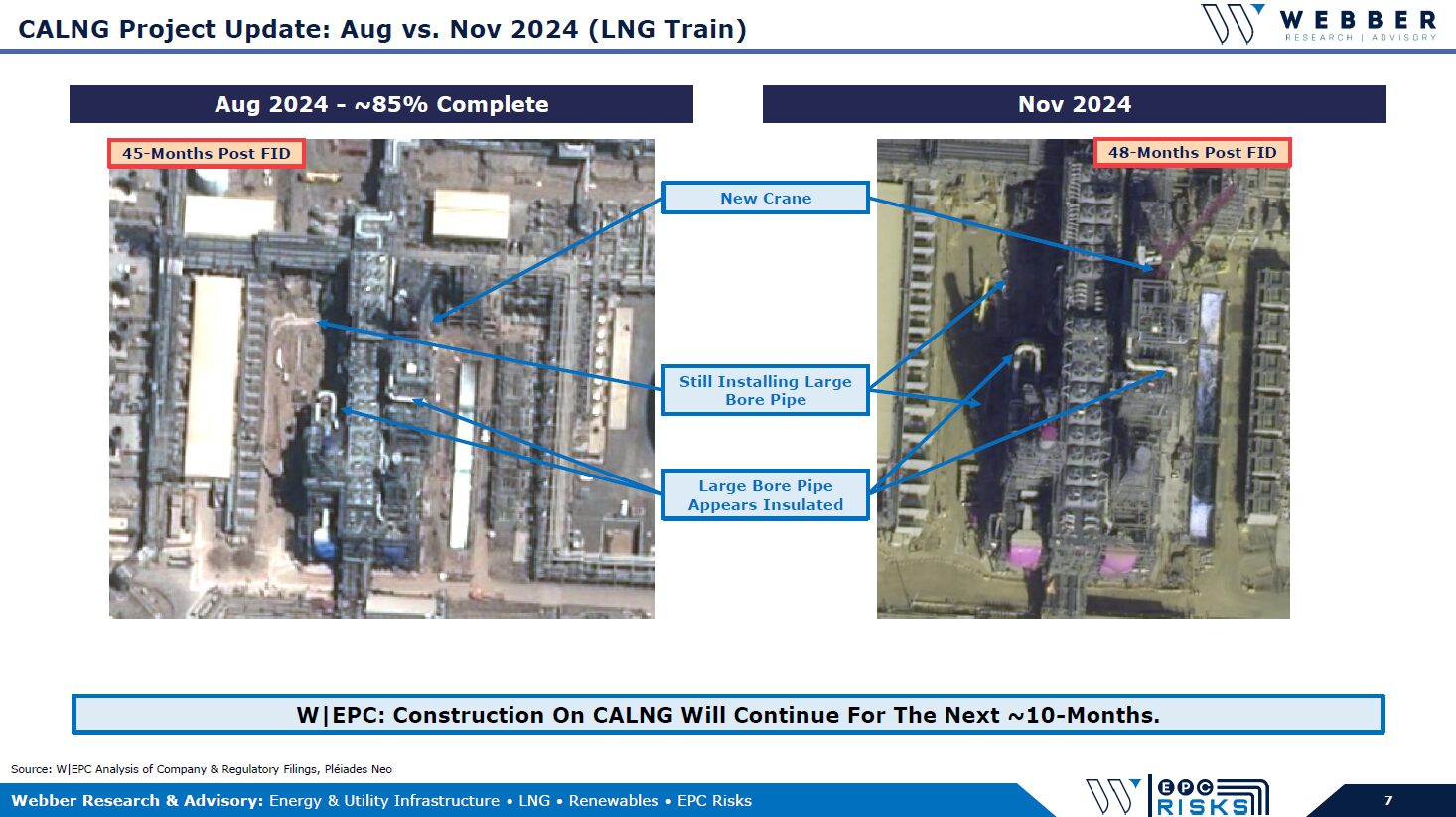

W|EPC: Costa Azul LNG – Q424 Project Review

If you’re already a Webber Research client, you can access this report via our Research Library. For access information, please contact us at [email protected] or [email protected]. For the full report, please visit our Downloads page.

Venture Global IPO & Trump 2.0: Assessing The Impact Across 35 LNG Projects

If you’re already a Webber Research client, you can access this 8-page report via our Research Library. For access information please contact us [email protected], or at [email protected].

W|EPC: LNG Canada Project Update – Q424

If you’re already a Webber Research client, you can access the full report in our Research Library. If you’re not yet a Webber Research subscriber, please contact us at [email protected] or at [email protected].

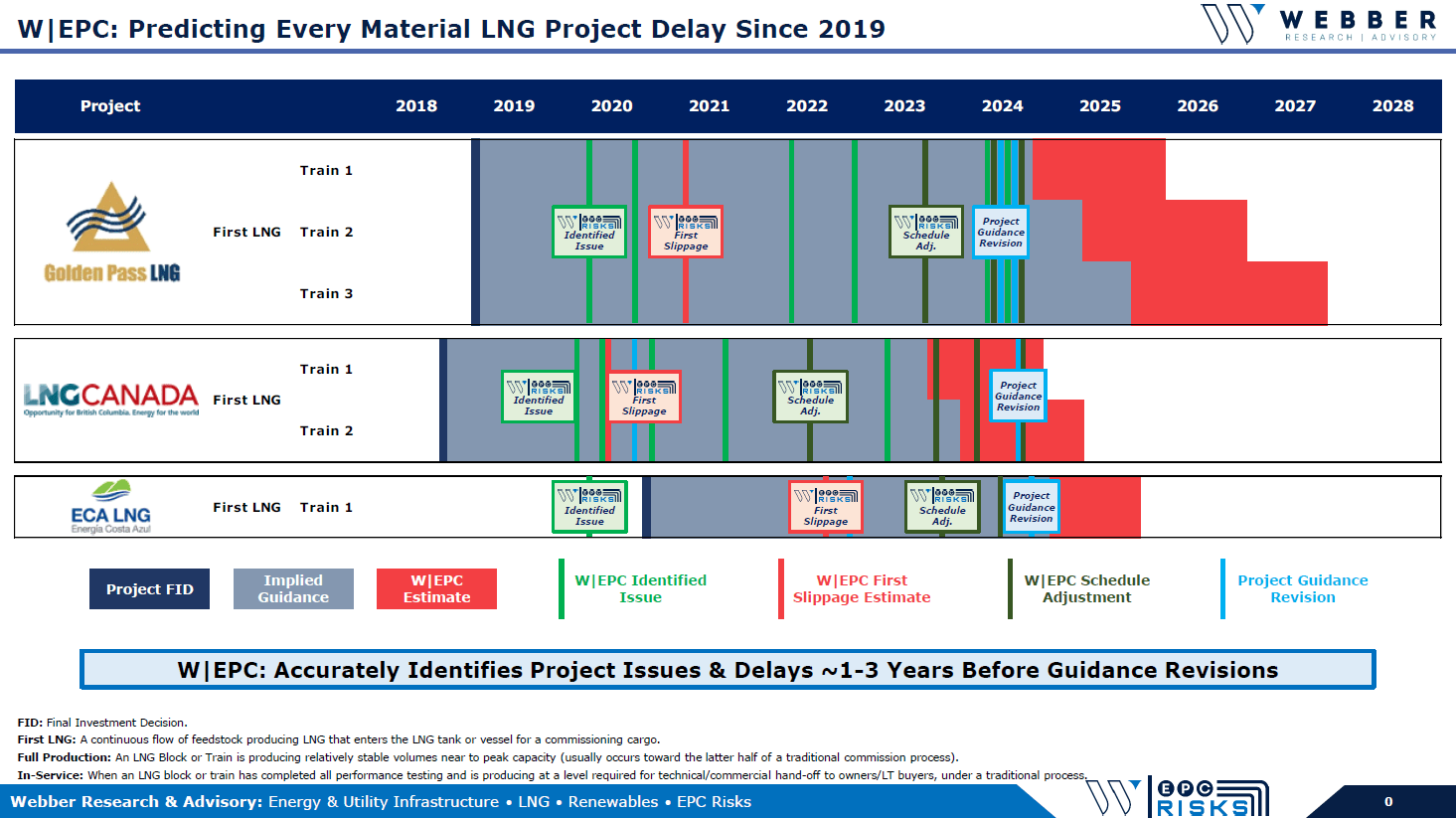

W|EPC: Predicting Every Material LNG Project Delay Since 2019

For access information please contact us at [email protected] or [email protected].

Read More

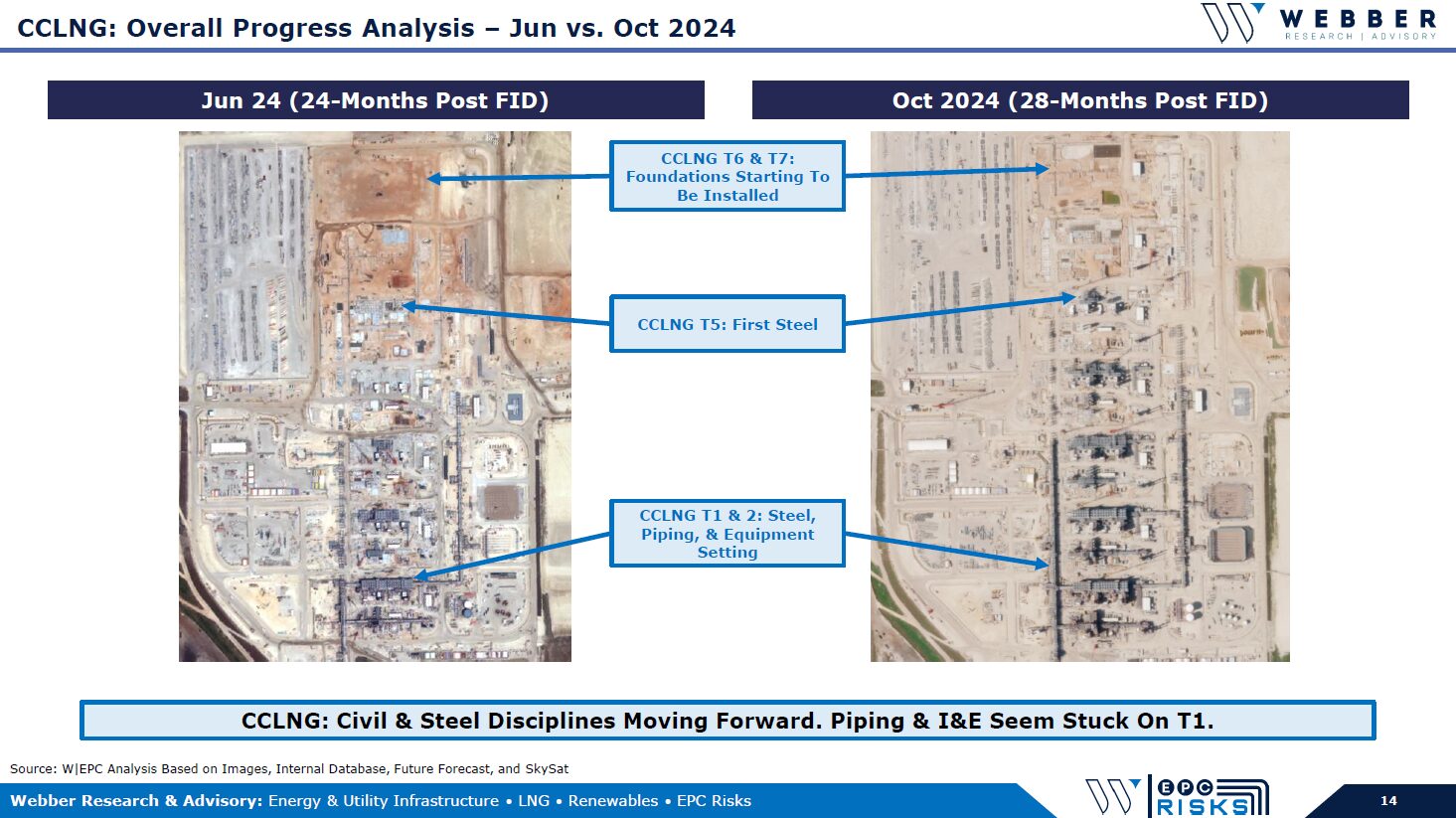

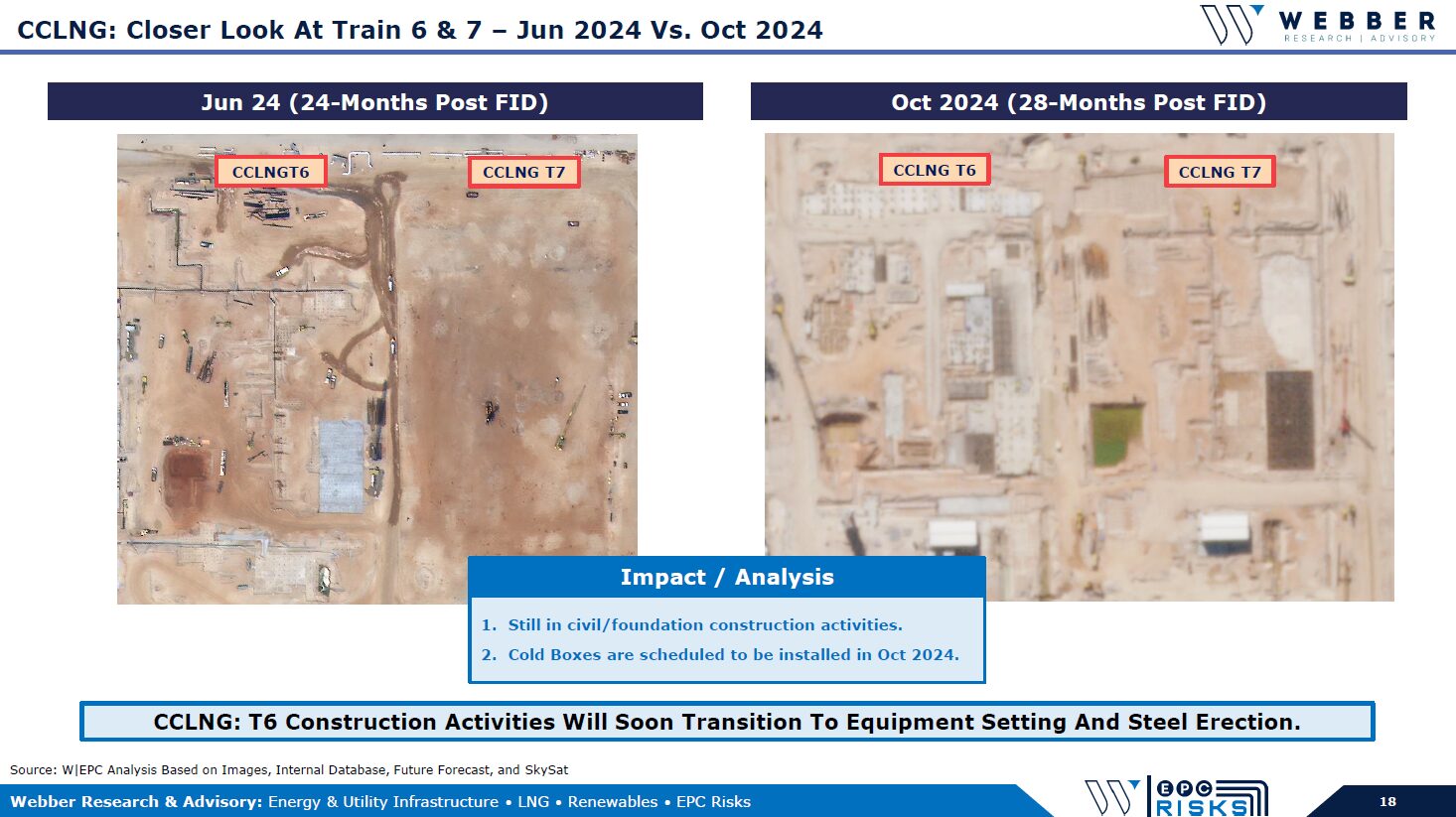

W|EPC: Corpus Christi LNG Project Update – Q424

If you’re already a Webber Research subscriber, you can access this report via our Research Library. To access the full report, please visit our Downloads page, or contact us at [email protected] or [email protected].

Read More

client log-in

client log-in